Description

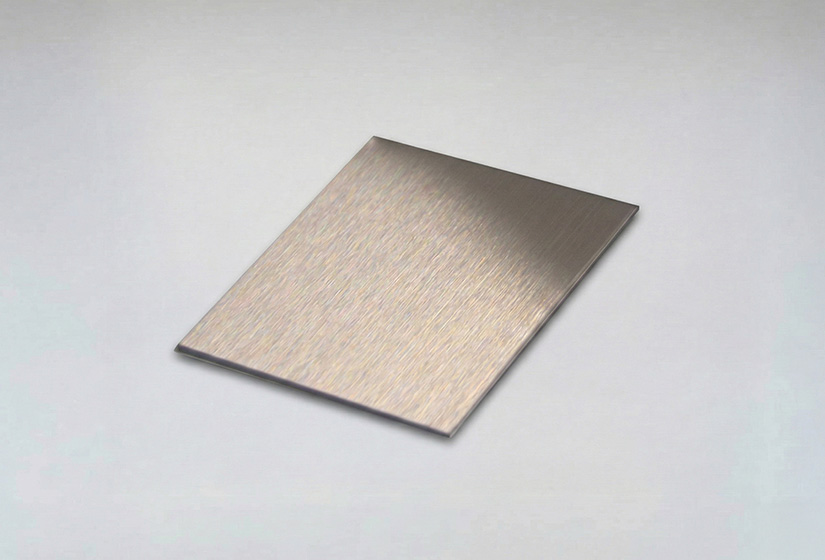

304/304L Stainless Steel

A widely used grade of austenitic stainless steel known for its excellent corrosion resistance, versatility, and good mechanical properties. It primarily contains 18-20% chromium and 8-10.5% nickel, which provide strong resistance to oxidation and corrosion in many environments. The “L” grade has reduced carbon content, which minimizes carbide precipitation during welding, but both grades are often supplied interchangeably.

316/316L Stainless Steel

An austenitic, molybdenum-bearing stainless steel known for its excellent resistance to corrosion, especially in chloride-rich and marine environments. It combines high strength, toughness, and good formability with reliable performance in high-temperature and chemical-exposure conditions. The “L” grade has reduced carbon content, which minimizes carbide precipitation during welding, but both grades are often supplied interchangeably. Together, 316/316L is widely used in marine hardware, food and pharmaceutical equipment, chemical processing, and medical devices where superior corrosion resistance and durability are critical.

310 Stainless Steel

An austenitic, high-chromium (24–26%) and high-nickel (19–22%) stainless steel designed for excellent resistance to oxidation, scaling, and creep at very high temperatures. It maintains good strength and toughness up to about 1100 °C (2010 °F) and resists sulfidation and carburization in moderately aggressive atmospheres. While its corrosion resistance is good, it is not as strong in chloride-rich or marine environments as 316 stainless steel. Common applications include furnace parts, heat exchangers, kilns, burners, and other high-temperature processing equipment.

430 Stainless Steel

A ferritic, straight-chromium stainless steel containing about 16–18% chromium. It offers good corrosion resistance in mildly corrosive environments, excellent resistance to oxidation, and good formability and machinability. Unlike austenitic grades, 430 is magnetic and has lower toughness, especially at low temperatures. It is not as resistant to chloride attack as 304 or 316 grades but is valued for its cost-effectiveness and decent performance in less demanding conditions. Typical uses include kitchen appliances, automotive trim, architectural applications, and household equipment

439 Stainless Steel

A ferritic stainless steel with about 17–19% chromium and very low carbon content, often stabilized with titanium or niobium to improve weldability and resistance to intergranular corrosion. Compared to 430, it has better formability, weldability, and corrosion resistance, particularly against stress corrosion cracking and in automotive exhaust environments. It is magnetic, has good resistance to oxidation and scaling at